Description

For Bambu Lab X1/X1C & P1P/P1S Upgrade Hotend Kit – Replacable Hardened Steel Nozzles 0.4mm

1. Precise Compatibility with Plug-and-Play Functionality

This upgraded Bambu Lab extruder hotend is specifically engineered for X1 Series (X1C/X1) and P1P printers. Adopting original equipment interface standards, it achieves seamless compatibility without requiring firmware adjustments, perfectly meeting the upgrade needs of original devices.

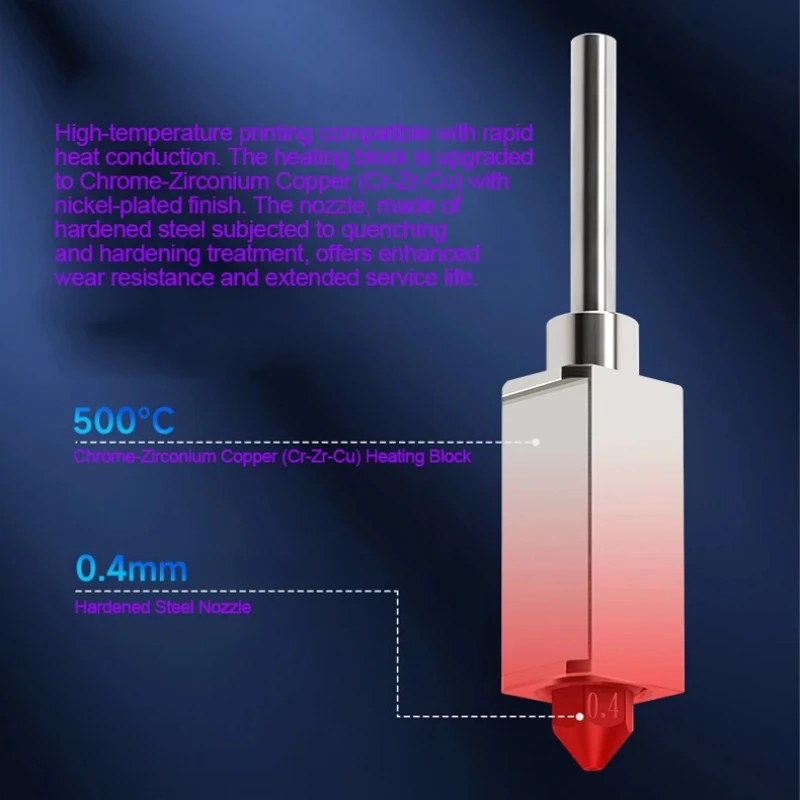

2. Hardened Steel Nozzle with High-Temperature Resistance and Wear Resistance

The core nozzle is crafted from SKD11 hardened steel, undergoing quenching and hardening treatment (hardness reaching HRC 58-62) with a maximum temperature resistance of 550℃. It not only accommodates abrasive filaments like carbon fiber (extending wear resistance lifespan by over 3x) but also supports high-temperature engineering materials such as PEEK, expanding printing applications.

3. Optimized Structure for Anti-Leakage and Anti-Clogging

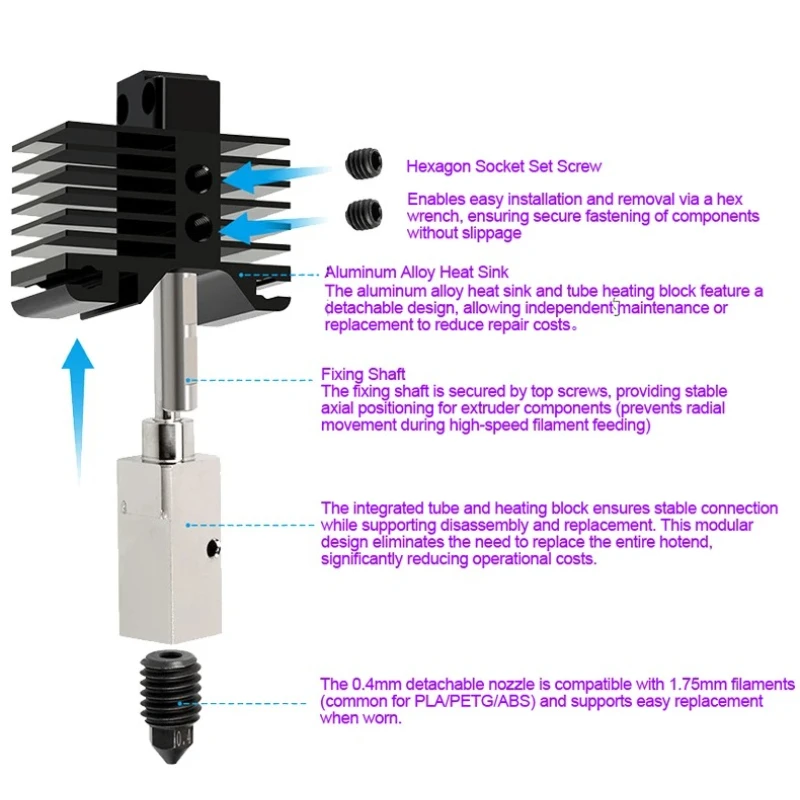

The throat tube and heating block feature an integrated one-piece design, with added step limitation and threaded connection at the joint. This dual-seal structure completely eliminates material leakage and component detachment issues common in traditional hotends. With an inner wall roughness of Ra 0.4 and ultra-thin 0.25mm wall thickness, the throat tube reduces filament feeding resistance and residue buildup, minimizing clogging risks.

4. Wide Compatibility with Diverse Filaments

Supports conventional materials including PLA, ABS, PETG, and TPU, as well as high-performance engineering filaments such as PP, PC, Nylon (PA), and PEEK. It caters to diverse printing needs from daily prototypes to industrial-grade parts.

5. Modular Design for Cost Efficiency

The nozzle features a detachable design, allowing individual replacement after wear without needing to replace the entire hotend. Core components like the heat sink and heating block support independent disassembly and maintenance, significantly reducing long-term operational and repair costs.